The integration of Artificial Intelligence (AI) into industrial automation is more than a trend—it’s a revolution. From predictive maintenance to intelligent robotics, AI is driving a new wave of efficiency, safety, and scalability in manufacturing and industrial operations. In this blog, we explore how AI is transforming industrial automation using recent statistics and trends.

📊1. Market Growth of AI in Industrial Automation

According to MarketsandMarkets, the AI in manufacturing market size is expected to grow from USD 3.2 billion in 2023 to USD 20.8 billion by 2028, at a CAGR of 45.6%.

The global industrial automation market, fueled by AI and machine learning, is projected to reach USD 265 billion by 2025.

This explosive growth highlights how industries are rapidly adopting AI-powered systems to gain a competitive edge.

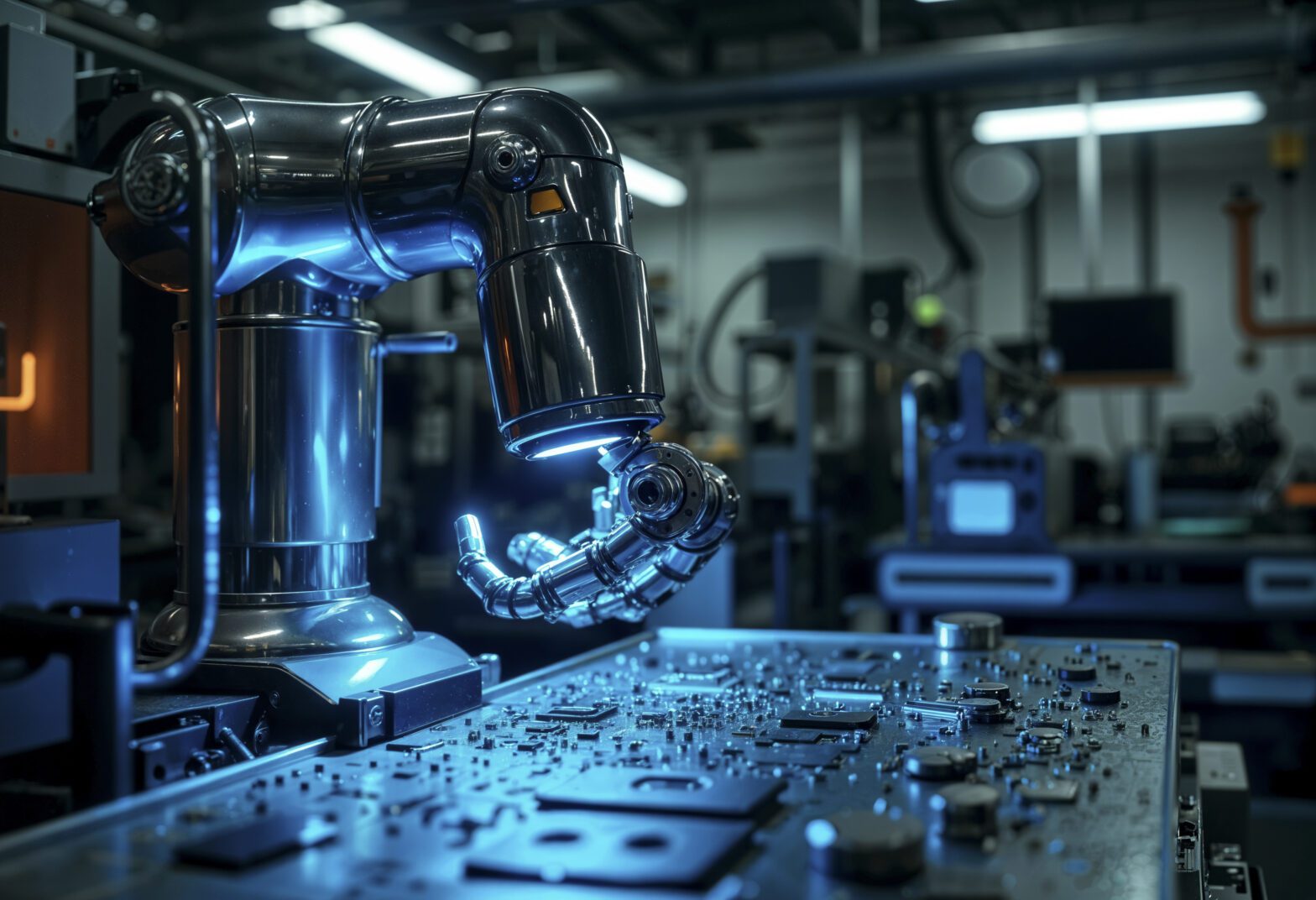

🤖2. Rise of Intelligent Robotics

AI-powered robots now account for over 25% of all industrial robots, compared to just 10% a decade ago (Statista, 2024).

A McKinsey report estimates that intelligent robots can reduce manufacturing errors by up to 90%, enhancing both speed and quality.

From assembly lines to warehouse logistics, smart robots are improving accuracy, reducing waste, and increasing production uptime.

🔧 3. Predictive Maintenance Using AI

Over 83% of manufacturers implementing AI have reported improvements in predictive maintenance (PwC, 2023).

Predictive maintenance powered by AI reduces downtime by up to 50% and extends machinery life by 20–40% (Deloitte Insights).

AI algorithms can detect early signs of equipment failure and schedule maintenance before a breakdown occurs, saving millions in repairs and lost productivity.

🧠 4. AI and Quality Control

AI-enabled vision systems improve defect detection rates by up to 90% compared to manual inspection.

55% of manufacturers report enhanced product quality after deploying AI-based quality control tools (Capgemini Research, 2023).

With deep learning, AI can inspect thousands of products per hour with unmatched consistency and accuracy.

🏭 5. Smart Manufacturing and Industry 4.0

67% of global manufacturers have adopted or are planning to adopt smart manufacturing initiatives powered by AI (IBM Institute for Business Value).

Smart factories using AI report a 20–30% increase in productivity and a 15–25% reduction in production costs.

AI is at the core of the Industry 4.0 revolution, enabling hyperconnected, data-driven manufacturing ecosystems.

📉 6. Labor Efficiency and Workforce Impact

AI-driven automation could boost global labor productivity by 40% by 2035 (Accenture).

However, automation may displace certain roles: 14% of current jobs could be automated, but new AI-enabled roles are also emerging rapidly.

Industries must balance automation with workforce reskilling and smart human-machine collaboration.

🚀 Conclusion: AI is the Future of Industrial Automation

AI is fundamentally reshaping industrial automation—not just by replacing manual tasks, but by redefining how entire systems operate. From predictive analytics and robotics to smart manufacturing and supply chain optimization, the impact is measurable and transformative.

Companies that embrace AI today are setting themselves up to lead the industry tomorrow.

+1(647)383-7986

+1(647)383-7986